You are here:

You are here:

Products List

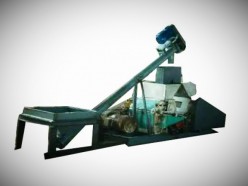

Best Automatic Sewing Machine

Best automatic sewing machine High-tech bagging machine Twin extruder machinery

Product description

Sewing machine is the stitching equipment for the plastic woven bag, paper bag, paper and plastic composite bag and so on.

Features:

1. Safe storage and good seal.

2. High efficiency and performance.

3. the bag is easy to open and bag can be reused.

4. High flexibility, simple operation.

5. high speed and small needle pitch.

Operating points:

(1) Threading: thread a needle firstly and then to the loop line, otherwise it will not work.

(2) The tension of the thread: the tension of thread is an important aspect for successful sewing, improper adjustment will cause disconnection and jumping.

Heavy material (such as sacks): the thread should be relaxed;

light material: the thread should be tight.

(3) The pressure of presser foot:

If the back of the stitching thread looks like scratched by the teeth of sewing machine or the stitch speed is slow, it means that the pressure is too high. In this time, you should release the needle plate and adjust screw;

If the suture is not straight or not uniform, you should tighten the needle plate spring and adjust screw to increase the pressure;

In addition, the pressure for sacks sewing or other heavy materials bag should be low as well as the pressure for plastic bags sewing plastic should be high.

(4) Adjust the looper: Turn the pulley in the operated direction and adjust the crank of the arm to make the needle in the specific position.

(5) Adjust the feed mechanism: to ensure that the feed teeth do not touch the needle board; There should be 1.5mm gap between the front teeth and the needle; the back needle should be lower 0.1mm than the front needle; the pin width can be adjusted from 7mm to 11.5mm.

(6) Adjust the scissors: In order to make the upper / lower blade holding-on, manually move the blade and when the two blades are holding-on , the gap between the end of two blades should be 0.1-0.2mm.

Related Production Line

Local delivery service sewing machine

Best crm high technology sewing machine

Best automatic local delivery service sewing machine

High technology sewing machine

Service

Before sales:

Give customers suggestion according to their inquire→Provide production design

During sales:

Arrange production according to the schedule and contract→Guide the installation and debug on site→Provide training to customers about how to use and maintain the equipment.

After sales:

Telephony solutions: To solve customer’s on-site problems through phone call. → Visiting solution: The after-sales department will pay a visit for problems which cannot be solved through phone call. → Telephone follow-up: Customer service staff will call back for feedback of problems solved through phone call. → Return visit: Irregular visit to customers or telephone follow-up for satisfaction survey.

Transportation

The equipment are shipped in standard export containers. The main and precise parts are packed in cases.

Learn more about us

Qinhuangdao Beidou Autocontrol Equipment Co., Ltd. Is a leading enterprise in the field of fertilizer blend machinery, one of the top 10 fertilizer machine manufacturers in China with 13 years manufacturing and designing experience. We are professional manufacturer of modern and high-tech formula fertilizer complete equipment, and so far we have got many patented awards. Choose us and you will have integrated product development, design, manufacturing, sales, installation and debugging into one. We can design and manufacture the equipments as per customer’s requirements.

Our productions

Best automatic BB fertilizer production line

Lamination water soluble fertilizer production line

Oem of fertilizer granulator machine

Powder automatic packing machine series

Superior performance bucket elevator system