What Is BB Fertilizer

What is BB Fertilizer

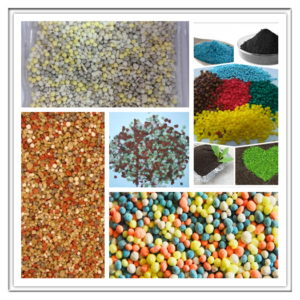

BB fertilizer, also called bulk blending fertilizer, is a kind of compound granular fertilizer mixed or blended by several simple fertilizers or compound fertilizers by certain proportion. It features granule uniformity, less water, moderate granule intensity, no agglomeration store, easy to use and low cost.

BB fertilizer is a development direction of fertilizer in future. It has advantages of total primary nutrients of

- Comprehensive nutrients, high concentration, raising yield and saving cost, and targeted fertilization. Bulk blending fertilizer contains over 52% of total effective ingredient compared with that contained in compound fertilizer of just 25%-48%. The proportion (N:P2O5:K2O =15:15:15) of the nutrients (effective ingredient) contained in compound fertilizer has too much phosphorus, which results in nutrients waste. The nutrient formula of BB fertilizer is made according to the soil nutrient proportion based on the need of crops, which is both scientific and targeted.

- BB fertilizer can be produced in easy process with low cost and non-pollution.

- Formula can be adjusted accordingly. It is alterable as per the crop nutrients, soil fertility and crop yield, thus making a good defect remedy for nutrient deficiency or nutrient excess caused by fixed nutrient ratio in the universal fertilizers. BB fertilizer can be used both as base fertilizer and additional fertilizer. When used as base fertilizer, top application is recommended instead of deep application owing to good solubility; when used for fruits, tea and vegetables, furrow application and hole application are better than broadcast application. The distance between bb fertilizer and seeds or crop root should be 3-5 mm, when application is done, get the fertilizer covered by soil. Additional fertilizer can be used in water. Unit application amount is only 60% of compound fertilizer.

What is Batch Type BB Fertilizer Machine

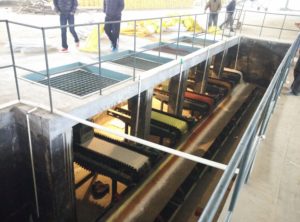

Beidou’s batch type BB (bulk blending) fertilizer machine is used to produce bulk blending fertilizer efficiently. It is designed according to different soil components in different areas and specific requirements of compound fertilizer factories and chemical fertilizer manufacturers..

How to Get Batch Type BB Fertilizer/Production Process

PLC controlled computer system > Automatic proportional batching raw materials > Lifting and conveyed by belt conveyor> Mixing by roller> Mixed materials disposed into storage silos of weighing machine >Quantitative packaging (10-50kg/bag) >Conveying and sewing > Finished product pelletizing storage.

Why Choose Our BB Fertilizer Machine?

1.It applies to chemical products, fertilizer, formulation fertilizer, feed.

2.it applies to different chemical products

3.High production efficiency.

4.Long working life.

5.high quality equipment

- perfect after-sale service

- unique three dimensional design

- We have 8 patented products and design

9.The most important part is mixing, on which the fertilizer’s uniformity and integrity rely. Our mixer is a patented product that makes the mixed fertilizer uniform and integrated.

- Our equipments meet different capacities ranging from 1-60 tons per hour.

- Customers can have customized machines according to the practical need.

- The whole line is automatic and controlled by computers.

- Patented accumulative packaging machine provides customers with precise weighing and solid closing bag. All weighing process is controlled perfectly by the program designed by our engineer.

- Strong technology team with excellent experts and engineers backing up.

Working Process of Bach Type BB Fertilizer Machine

- Put materials into each raw materials silo separately by manual.

- Then the raw materials get discharged from the bins into the weighing hopper according to the ratio of weight in order.

- After complete batching, the materials are weighed by the weighing hopper and conveyed by a conveying belt to bucket elevator or inclined belt conveyor to mixing machine. Meanwhile the batching system continues to start a new round batching.

- When mixing finished, the mixed materials are transported to the weighing and packaging silo and go into the weighing, packaging, conveying and sewing process to finish the batching job.

- Then batch mixing followed cycle by cycle.

Application Range of Batch Type Production Line

This batch type mixing packaging production line is mainly for BB fertilizer, Compound Fertilizer, Formulated Fertilizer by soil testing, drip irrigation fertilizer, chemical product, feed and other industries.

Technical Parameters of Batch Type BB Fertilizer Production Line

| Model | BPHB10 | BPHB15 | BPHB30 |

| Types of raw material | 3-8 types | 3-8 types | 3-8 types |

| Producing capacity | 10-15 t/h | 15-20 t/h | 20-35 t/h |

| Weighing range | 5-50kg | 5-50kg | 5-50kg |

| Weighing accuracy | 0.2% | 0.2% | 0.2% |

Previous Basic Knowledge on Fertilizer

Next What is mixed fertilizer or blended fertilizer and how to get